Aim: To study the general introduction of total station survey.

Introduction:

A total station is an electric/optical instrument used in modern surveying. It is also used

by archaeologists to record excavations as well as by police, crime scene investigators, private

accident deconstructionists and insurance companies to take measurements of scenes.

Furthermore, they can make computations with angle and distance measurements and

display the result in real times.

They are used for;

Topographic Surveys

Hydrographic surveys

Cadastral surveys

Construction surveys

The total station is an electric Theodolite (transit) integrated with electric distance meter (EDM)

to read distance from the instrument to a particular spatial entity. Some models include internal

electric data storage to record distance, horizontal angles, and vertical angle measured, while

other models are equipped to write these measurements to an external data collector, which is a

hand-held computer.

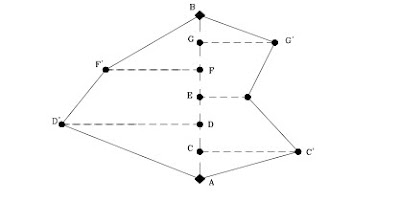

Angles and distance are measured from total station to points under survey, and the coordinates

(X,Y and Z or northing, easting and elevation) of surveyed points relative to the total station

position are calculated using trigonometry and triangulation.

Data can be downloading from the total station to a computer and application software used to

compute results and generate a map of the surveyed area.

Most modern total station instruments measure angles by means of electro-optical scanning of

extremely precise digital bar-code etched on rotating glass cylinders or disc within the

instrument. The best quality total stations are capable angles to 0.5 arc-second. Inexpensive

“construction grade” total station generally measure angles to 5 or 10 arc-second.

Measurements of distance is accomplished with a modulated microwave or infrared carrier

signal, generated by a small solid- state emitter within the instrument’s optical path, and reflected

by prism reflector or object under survey. The modulation pattern in the returning signal is read

and interpreted by the onboard computer in the total station. The distance is determined by

emitting and receiving multiple frequencies, and determining the integer number of wavelengths

to the target for each frequency. Most total stations use purpose-built glass porro’s prism

reflectors for the EDM signal, and can measure distance to a few kilometers. The typical total

station can measures to about 3 millimeters 1/1000th of a foot.

Reflector less total stations can measure distances to any object that is reasonably light in color,

to a few hundred meters.

Characteristics of Total Station Instrument:

They combine three basic components:

1. an electric distance measuring

2. an electric angle measuring components

3. a computer or microprocessor

These devices can automatically measure horizontal and vertical angles, as well as slope distance

from the single setup.

Parts of a total station instrument

The upper part of total station instrument (alidade) includes

1. Telescope

2. Graduated circle

3. All other elements necessary for measuring angle and distances.

Functions performed by total station instruments

1. In additional to providing guidance to the operator, microprocessors of total stations can

perform many different types of computations;

2. Averaging of multiple angle and distance measurements

3. Correcting electronically measured distances for prism constants, atmospheric pressure

and temperature.

4. Making curvature and refraction corrections to elevations determined by trigonometric

leveling.

5. Reducing slope distances to their horizontal and vertical components.